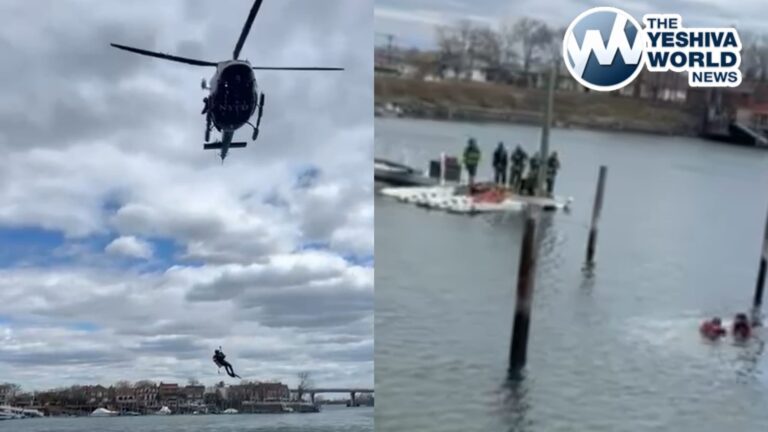

On a tributary of the Hudson River, a tugboat powered by ammonia eased away from the shipyard dock and sailed for the first time to show how the maritime industry can slash planet-warming carbon dioxide emissions.

The tugboat used to run on diesel fuel. The New York-based startup company Amogy bought the 67-year-old ship to switch it to cleanly-made ammonia, a new, carbon-free fuel.

The tugboat’s first sail on Sunday night is a milestone in a race to develop zero-emissions propulsion using renewable fuel. Emissions from shipping have increased over the last decade — to about 3% of the global total according to the United Nations — as vessels have gotten much bigger, delivering more cargo per trip and using immense amounts of fuel oil.

CEO Seonghoon Woo said he launched Amogy with three friends to help the world solve a huge, pressing concern: This backbone of the global economy has not started to transition to clean energy yet.

“Without solving the problem, it’s not going to be possible to make the planet sustainable,” he said. “I don’t think this is the problem of the next generation. This is a really big problem for our generation.”

The friends met while studying at the Massachusetts Institute of Technology. In their free time during the COVID-19 pandemic, they brainstormed how to power heavy industries cleanly. They launched their startup in November 2020 in a small space at the Brooklyn Navy Yard. The name Amogy comes from combining the words ammonia and energy.

They looked for a boat and found the tug in the Feeney Shipyard in Kingston, New York, languishing without a mission. It could break ice, but little to no ice has formed on that part of the Hudson River in recent years, so it was available for sale.

“It represents how serious the problem is when it comes to climate change,” Woo said. The project, he said, is “not just demonstrating our technology, it’s really going to be telling the story to the world that we have to fix this problem sooner than later.”

They named the tugboat NH3 Kraken, after the chemical formula for ammonia and their method of “cracking” it into hydrogen and nitrogen. Amogy uses its ammonia in a fuel cell, making the tug an electric-powered ship. The International Maritime Organization set a target for international shipping to reach net-zero greenhouse gas emissions by, or close to, 2050.

Shipping needs to cut emissions rapidly and there are no solutions widely available today to fully decarbonize deep-sea shipping, according to the Global Maritime Forum, a nonprofit that works closely with the industry. There is a lot of interest in ammonia as an alternative fuel because the molecule doesn’t contain carbon, said Jesse Fahnestock, who leads the forum’s decarbonization work.

Ammonia is widely used for fertilizer, so there is already infrastructure in place for handling and transporting it. Ton for ton, it can hold more energy than hydrogen, and it can be stored and distributed more easily.

“It certainly has the potential to be a main or even the main fuel,” Fahnestock said. “It has a potentially very friendly greenhouse gas footprint.”

Ammonia does have drawbacks. It’s toxic. Nearly all of it currently is made from natural gas in a process that is harmful for the climate. And burning it has to be engineered carefully or it, too, yields traces of a powerful greenhouse gas.

Amogy’s technology is different.

The tugboat runs on green ammonia produced by renewable electricity. A 2,000-gallon tank fits in the old fuel tank space, for a 10-to 12-hour day at sea.

It splits liquid ammonia into its constituents, hydrogen and nitrogen, then funnels the hydrogen into a fuel cell that generates electricity for the vessel without carbon emissions. The process does not burn ammonia like a combustion engine would, so it primarily produces nitrogen in its elemental form and water as emissions. The company says there are trace amounts of nitrogen oxides that it’s working to completely eliminate.

Amogy first used ammonia to power a drone in 2021, then a tractor in 2022, a semi-truck in 2023, and now the tugboat to prove the technology. Woo said their system is designed to be used on vessels as small as the tugboat and as large as container ships, and could also make electricity on shore to replace diesel generators for data centers, mining and construction, or other heavy industries.

The company has raised about $220 million. Amazon, an enterprise with immense needs for shipping, is among the investors. Nick Ellis, principal of Amazon’s $2 billion Climate Pledge Fund, said the company is excited and impressed by what Amogy is doing. By investing, Amazon can show ship owners and builders it wants its goods delivered with zero emissions, he added.

“Many folks will now get a chance to see and understand how real and promising this technology is, and that it could actually be in container ships or tugboats in a matter of a few years,” he said. “If you would’ve asked five years ago, I think a lot of people would have thrown up their hands … And suddenly we have not only a compelling example, but a commercially-viable example. These types of things don’t come by every day.”

Other companies are developing ammonia-powered ships that still use some diesel.

In Singapore in March, Fortescue’s Green Pioneer vessel showed how ammonia could be used in combination with diesel as a marine fuel. An ammonia-powered container ship, the Yara Eyde, will be on water in 2026 with an engine running on green ammonia, according to Yara Clean Ammonia. In Japan, the NYK Group converted the tugboat Sakigake to run on ammonia rather than liquified natural gas.

As a next step, Amogy is working with major shipbuilders to bring ammonia power to the maritime sector. South Korean shipbuilder Hanwha Ocean is purchasing its technology. HD Hyundai and Samsung Heavy Industries are working with Amogy on ship designs.

Sangmin Park said that because Amogy has made significant progress in proving ammonia’s potential as a clean fuel, “we expect the industry to move towards adoption more quickly.” Park is senior vice president at HD Hyundai subsidiary HD Korea Shipbuilding & Offshore Engineering.

“For the past few years, the industry has recognized the potential of ammonia as a zero-carbon fuel,” Park wrote in an email, “but actually building and sailing the first vessel is a true landmark event.”

(AP)

One Response

The two main sources of ammonia are to produce using the Haber Bosch method which is energy intense or a catalytic process which requires hydrocarbons.

So, instead of creating a “green” fuel, they have just created a more inefficient fuel type.