Have you ever wondered how industries manage to move various liquids, from water to thick slurries, without a hitch? The secret lies in a piece of equipment known as the diaphragm pump. Regardless of your industry, understanding how these pumps operate can give you valuable insights into their role in keeping things running smoothly.

This article discusses what a diaphragm pump is and explores its diverse industrial applications. So, if you’re curious about how these pumps make industrial processes more efficient, you’re in the right place. Dig in to discover the fascinating world of diaphragm pumps!

What Is A Diaphragm Pump?

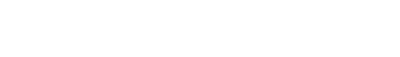

Do you know how your heart pumps blood throughout your body? A diaphragm pump works in a similar way. Imagine a flexible diaphragm membrane constantly moving up and down. When it moves upwards, it creates a vacuum that sucks fluid in through an inlet valve. Then, as it moves back down, it forces that fluid out through an outlet port.

This repetitive motion is how diaphragm pumps work their magic. They’re sturdy and can handle all sorts of liquids – thick ones and those with solid bits floating around. The key is that the rubber, plastic, or Teflon diaphragm continuously flexes to move the liquid.

But before you get started, consider doing your due diligence on diaphragm pump parts and functions to understand how they operate and what maintenance they require. Familiarizing yourself with the pump will help ensure safe and proper usage when handling hazardous materials. Take your time to educate yourself first for secure chemical transfers.

Industrial Applications Of Diaphragm Pumps

Here are some of the areas that use diaphragm pumping applications:

Chemical Processing

When dealing with harsh chemicals like acids, bases, or solvents, you need equipment that can handle the job. That’s where diaphragm pumps come in handy. These rugged pumps can transfer even the most corrosive fluids without leaks or safety issues.

Diaphragm pumps have a smart design that keeps hazardous liquids fully contained as they flow from one place to another—there’s no risk of dangerous spills or exposures. Whether in a chemical industry, lab, or any other situation with harsh chemicals, diaphragm pumps are the way to go.

Food And Beverage Processing Industry

The food and beverage processing sectors prioritize hygiene, making pumps that prevent contamination essential. For instance, smoothie bars use pumps to transfer thick fruit purees safely. Breweries rely on pumps that won’t taint beer flavors. And bakeries need equipment that maintains sanitation while handling heavy batters.

Diaphragm pumps can easily clean and handle viscous liquids without risking contamination. They ensure products meet stringent quality standards consumers expect. With proper pump selection, businesses can move ingredients while upholding exceptional cleanliness.

Water Treatment

The water purification industry has unique equipment to get the job done right, and diaphragm pumps are one key player in the purification process.

These pumps accurately add measured amounts of chlorine, lime, and other purification chemicals to the water supply. Their ability to transfer aggressive, thick chemicals without issue ensures sufficient and safe water treatment.

Diaphragm pumps play a critical role in accurately putting the right purification chemicals into the water. Water treatment wouldn’t be nearly as effective without the reliable performance of these robust pumps.

Pharmaceutical Industry

Accuracy and immaculate cleanliness are priorities in pharmaceutical manufacturing. Diaphragm pumps excel in this domain by precisely measuring and transferring delicate liquids and compounds.

Imagine administering vital medications or producing life-saving treatments—even a trace of impurities can be catastrophic. These pumps prevent cross-contamination, ensuring product integrity.

In sterile environments like research facilities or manufacturing plants, their ability to maintain purity is indispensable. Whether handling volatile solvents or sensitive reagents, diaphragm pumps deliver the reliability and precision this critical industry demands.

Oil And Gas Industry

Harsh working conditions are the norm in the oil and gas industry, equipment must be rugged and dependable to handle demanding fluid transfers. Diaphragm pumps rise to the occasion, expertly handling thick sludges, viscous oils, and harsh chemicals.

Picture an offshore rig battling fierce ocean conditions—these pumps power through with ease. Their robust design thrives in unforgiving environments like refineries and drilling operations.

Whether transferring thick crude or carefully handling hazardous substances, diaphragm pumps ensure safe, efficient fluid movement. They operate flawlessly, from scorching desert heat to freezing offshore platforms. Their durable construction is no match for their extreme temperatures, pressures, and acidic materials.

Paint And Coating Industry

The paint and coating industry relies on precision and consistency to create flawless finishes. Diaphragm pumps excel in this field, effortlessly moving thick paints, glossy varnishes, and protective coatings. On bustling factory floors, these versatile pumps handle even the stickiest materials without a hitch, ensuring vibrant colors flow smoothly through production lines.

Quality is crucial in this sector. Whether applying a delicate glaze to fine China or coating massive industrial equipment, diaphragm pumps deliver steady, reliable flow. This consistency guarantees even coverage and a perfect end product every time.

From automotive finishes to home decor, these pumps tackle diverse applications with ease. So, the next time you want to add some color to your outside kitchen, stop to appreciate the intricate process behind that perfect finish. Diaphragm pumps” ability to maintain performance, even with high-viscosity materials, makes them indispensable.

Conclusion

Diaphragm pumps play a crucial role in different industries. Their simple yet effective design makes them essential for tasks like moving harsh chemicals in processing plants and ensuring the purity of pharmaceuticals. These versatile and reliable pumps handle everything from water treatment to thick paints and coatings.

By understanding how diaphragm pumps work and their applications, you can appreciate their importance in maintaining smooth and safe industrial processes. Whether you’re in chemical processing, food production, or oil and gas, these pumps ensure efficiency and precision, making them indispensable in modern industry.